Start from scratch

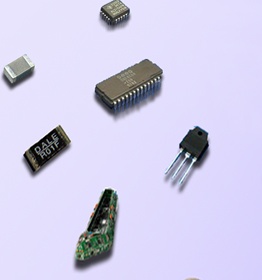

Nearly 20 years of electronic component manufacturing experience!

Taitech is from the basic material to carry out research and development

A strong foundation is more practical to go Taitech

Therefore, Taitech manufacturing high precision micro components technology in a relatively advanced position.

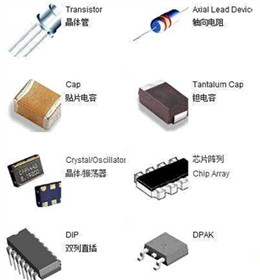

&ldquo for manufacturing high-end electronic components; 4 core technologies, ”.

Magnetic material, film manufacturing process, ferrite fabrication, and lamination of electronic components.

Taitech also use high precision instruments, the challenge of various electronic components!

Material technology

Accumulation of history and technology over the past 20 years.

Taitech material technology, found a variety of properties of materials from the atomic level.

For example, in the material design stage, through the ratio of main raw materials and the control of micro additives.

All the results are more than 20 years, and through numerous experiments and research accumulated technology.

This is a strong core competitiveness of Taitech.

Process technology

Implementation of nanotechnology control.

Processing technology features digging out material characteristics

For example, a film is formed on the wafer and an electrode, a coil, a head material, etc. are formed.

The thin film element also has the corresponding application.

Production technology

Outsourcing excellent brands, manufacturing products, production equipment.

The manufacture of excellent products requires excellent production equipment.

In order to produce every electronic component, we are willing to buy equipment with high price and excellent brand.

And through the technical absolute hard enough technical professionals for professional debugging, and strive to produce every product is perfect.

Through the further improvement of QCD (quality ·, cost ·, delivery), and promote the integrated production from materials to products.